Operational Gains from PLC Programming Updated to IEC 61131-3 Standards

Efficiency in automation doesn’t just come from the hardware on the factory floor—it often starts in the logic that drives it. Updating PLC programming to align with the IEC 61131-3 standards changes how control systems are built, maintained, and expanded. It’s about making code smarter, more reusable, and easier to work with while ensuring long-term adaptability across platforms.

The Power of Code Reusability in IEC 61131-3

The IEC 61131-3 standard introduces a structure that encourages programmers to create reusable code blocks. Instead of writing unique logic for every single task, engineers can build modular code components that can be applied across multiple projects. This approach reduces repetitive work and keeps programming more consistent, whether it’s for a custom PLC solution or a large-scale system.

A PLC programming company working within this standard can develop libraries of proven code that speed up project delivery. For clients using platforms such as Rockwell Allen Bradley PLC systems, reusability means fewer errors and quicker debugging since tested blocks can be dropped into new projects with minimal adjustments. Over time, this builds a reliable foundation that benefits both the programmer and the end user.

Streamlining Maintenance and Troubleshooting with Standardized Logic

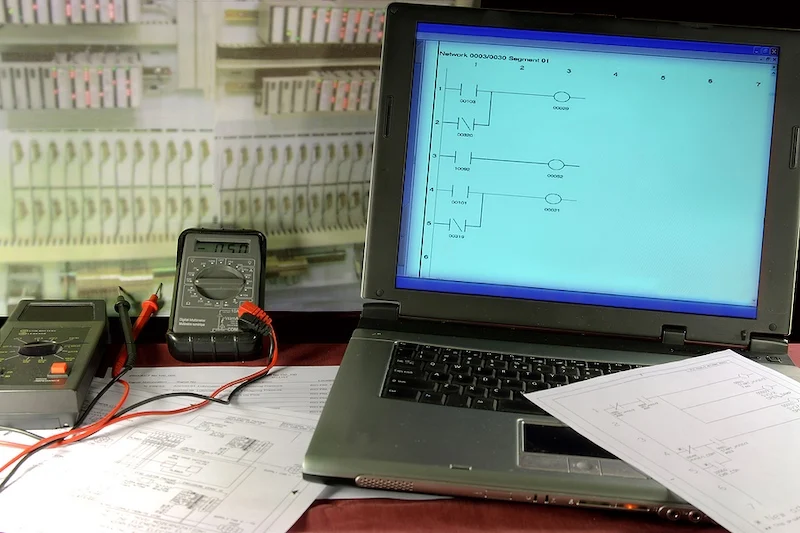

Standardized logic brings a level of predictability that makes maintenance faster and less complex. With IEC 61131-3, the programming language structure stays consistent across projects, which helps technicians quickly locate the cause of faults. This is especially valuable in high-pressure situations where downtime costs money by the minute.

For operations running multiple PLC systems, including custom PLC units and Rockwell Allen Bradley PLC controllers, the ability to read and understand standardized code reduces reliance on specialized knowledge. Any trained technician familiar with the standard can step in and make adjustments, cutting downtime and keeping production running smoothly without unnecessary delays.

Boosting Efficiency Through Structured and Modular Programming

Structured and modular programming allows projects to be broken into smaller, manageable sections. In the IEC 61131-3 framework, this means organizing code into functional modules that handle specific tasks, such as motor control or data acquisition. This separation makes it easier to manage updates without affecting unrelated parts of the system.

By using this method, a PLC programming company can work on different sections of the code in parallel, reducing development time. Structured programming also improves clarity, making it easier for both current and future engineers to understand the logic flow. For businesses upgrading their systems, this translates into faster commissioning and smoother long-term operation.

Enhancing System Reliability with Standardized Function Blocks

Function blocks within IEC 61131-3 are pre-tested units of code that perform specific operations reliably. These blocks can handle anything from mathematical calculations to control algorithms, and because they’re standardized, they reduce the chance of introducing new errors during updates.

Whether implementing a new Rockwell Allen Bradley PLC or maintaining a custom PLC setup, standardized function blocks improve confidence in the system’s performance. They also simplify compliance with safety standards, as proven and consistent code reduces the risk of unforeseen failures in critical operations.

Achieving Interoperability Across Diverse PLC Platforms

One of the significant advantages of adhering to IEC 61131-3 is improved interoperability between different PLC brands and models. Because the standard defines how programming languages are structured, engineers can transfer knowledge and even code from one platform to another with minimal rewriting.

This is especially important for facilities using a mix of hardware, such as integrating Rockwell Allen Bradley PLC units with other manufacturers’ systems. Interoperability reduces vendor lock-in and opens the door to more flexible system expansions, ensuring companies can choose the best hardware for their needs without worrying about software compatibility.

Faster Deployment and Scalability with IEC 61131-3

Projects developed under IEC 61131-3 can be deployed more quickly because the structure allows for parallel work and simplified integration. Teams can reuse tested modules, integrate standardized function blocks, and maintain a consistent programming style across the project. This shortens commissioning time and helps systems go live without extended delays.

Scalability is equally improved. When operations expand or new equipment is added, the modular nature of the programming means new components can be integrated with minimal disruption. For companies looking to grow, this flexibility ensures they don’t have to overhaul their control systems to accommodate new processes.

Future-Proofing Your Operations with an Open Standard

IEC 61131-3 is an open standard, meaning it’s widely adopted and not tied to a single manufacturer. This ensures that the skills, code libraries, and tools developed today will remain relevant in the future. Companies investing in custom PLC solutions benefit from knowing their control logic can evolve alongside technology without being locked into outdated systems. For any operation working with a PLC programming company, adopting this standard means staying adaptable in the face of industry changes. As automation technology advances, having a foundation built on an open and widely supported standard allows businesses to update their systems confidently, without starting from scratch.