Exploring the World of Antique Hardware Manufacturers

Antique hardware manufacturers specialize in producing and reproducing hardware items such as doorknobs, includingbrass decorative hinges, locks, and handles that were commonly used in the past. These manufacturers often use traditional techniques and materials to create authentic-looking antique hardware for use in historic buildings or for homeowners looking to add a vintage touch to their homes.

History of Antique Hardware Manufacturing

Antique hardware manufacturing has a long history that dates to the time of human civilization. The Egyptians, Greeks, and Romans all used metal hardware to adorn their doors, windows, and furniture. During the Middle Ages, blacksmiths began to produce iron hardware, such as hinges and locks, for use in castles and churches.

In the United States, antique hardware manufacturing began in the early 19th century. Companies such as Yale, Corbin, and Russwin began to produce locks, doorknobs, and other hardware items in large quantities for use in homes and public buildings. These companies often used traditional techniques such as sand casting, die-casting, and forging to create their products.

Types of Antique Hardware

Antique hardware can be classified into several categories based on the materials used, the type of product, and the period of history it represents. Here are some of the most ordinary types of antique hardware:

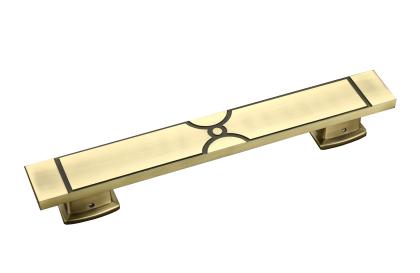

- Door Hardware: This includes doorknobs, handles, hinges, locks, and latches.

- Window Hardware: This includes sash locks, sash lifts, and pulleys.

- Furniture Hardware: This includes handles, drawer pulls, and hinges.

- Lighting Hardware: This includes chandeliers, wall sconces, and lamp parts.

- Plumbing Hardware: This includes faucets, showerheads, and sink parts.

Manufacturing Techniques

Antique hardware manufacturers often use traditional manufacturing techniques to create their products. These techniques can include sand casting, die-casting, forging, and stamping. Sand casting involves pouring molten metal within a sand mold, while die-casting involves injecting molten metal into a metal mold. Forging involves heating and shaping a piece of metal with a hammer and anvil, while stamping involves pressing metal sheets into shape.

Materials Used

Antique hardware can be made from a variety of materials, including brass, bronze, iron, and steel. Brass was a popular material for hardware during the Victorian era due to its durability and ability to resist corrosion. Bronze was also commonly used, particularly in the Arts and Crafts movement of the before time 20th century. Iron was a popular material for door and window hardware in the 19th century, while steel was commonly used for locks and hinges.

Reproduction Hardware

In addition to creating authentic antique hardware, many manufacturers also produce reproduction hardware that is designed to look like antique pieces. These items are often made using the same techniques and materials as the originals, but are not antique. Reproduction hardware can be a good option for homeowners who want a vintage look without the high cost of genuine antique hardware.

Conclusion

Antique hardware manufacturers play an essential role in preserving the history and heritage of our buildings and homes. Using traditional manufacturing techniques and materials, they can create authentic-looking hardware that is functional and aesthetically pleasing. Whether restoring an old house or simply adding vintage charm to your living space, antique hardware can provide a unique and timeless touch.