What Is A Torque Wrench?

A torque is an apparatus used to apply an explicit torque to a latch, for example, a nut or screw. A torque is utilized where the snugness of screws and fasteners is critical. It allows the user to set the torque applied to the fastener so it can be matched to the details for a specific application. In common life, a person mostly appreciates the work of torque wrench when it comes to open the jar, which is hard to open or seal again. But how do they work, let’s discuss it further?

How do torque wrench works?

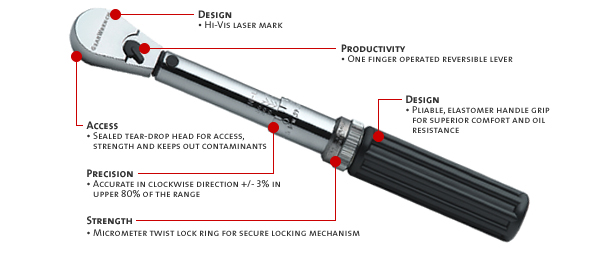

As torque wrenches come in so many shapes and styles, so their application depends on the style one is using. The basic or standard torque wrench is been around since the late 1920s and has been very popular since then. A basic or standard torque wrench looks similar to a socket wrench, but is an advanced version of it and has some extra features.

The most important difference between the two is the handle, which in torque wrench is made of more elastic material which responds when the force is applied to it. While towards the head it has yet another arm that isn’t affected by the torque and remains parallel to the arm itself. This arm reflects the amount of torque applied and matches to a gauge toward the base of the handle.

When comparing the amount of “flex” in the handle, as opposed to the arm, the amount of torque is determined. Now, this is the basic working of a basic torque wrench. While apart from standard torque wrench, there are many different styles of the torque wrench and they all have their own style of working. Some of them are digital and some of them are mechanical and each one of them has its own use, purpose, and style.

Types of the torque wrench

There are three basic types of the torque wrench, plus “torque stick”, that are used in the automotive industry.

- Beam Type:- A pointer beam at the wrench head is attached, as the wrench itself is twisted, so the beam stays at the place and the scale beneath the pointer moves to indicate the amount of twist, or torque, is applied.

- Dial Indicator:- A rearranged bar type, with a dial joined to the instance of the torque, to indicate the amount of twisting the wrench handle is going through.

- Clicker- Type:- This unit has a spring-loaded lever, which can be adjusted by twisting the handle to the desired torque reading. When the amount of twist is achieved, the spring-loaded lever breaks free, creating a clicking sound.

- Torque Sticks (or Torque Limiters):- These are little torsion bars embedded between more often than not an air torque the sort utilized for tire substitution or hand air torques and furthermore, an attachment. Each torsion bar has its own twist setting, and when used, will “bounce back” the socket, instead of tightening it any further.

0 comments