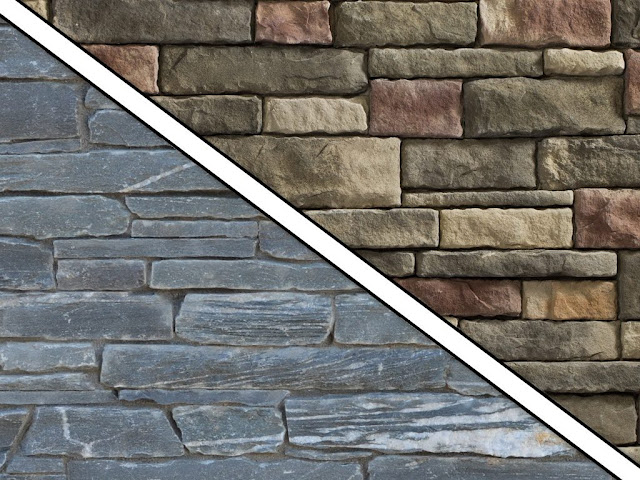

Natural Stone vs. Manufactured Stone – Which One Is Better?

It is a lifelong debate when you are going to make a selection for the use of stones in your constructions. Somewhere natural stones seem a better choice while somewhere manufactured/artificially made stones. Let’s check the pros and cons of both options in the current post and reach at a fruitful decision before the commencement of the building project.

Introduction:

When you plan to build a home, office, or a business unit, you might have encountered various options for material selection. RCC structural frames are now common everywhere. It follows a set of options for other materials and architectural practices.

However, expensive and classic looking houses, as well as offices, still adhere to use natural stones instead of or in a combination of the cement-concrete structure. If your affinity towards natural materials, then the selection dilemma persists between natural stones and manufactured stones.

What is Natural Stones?

We know natural stones are 100% stones come from quarries and applied by masons with a little modification in constructions.

What is Manufactured Stones?

You may wonder that what the manufactured stones are after all. Cultured stones, architectural stones, and veneer are other colloquial names of manufactured stones.

Artificial stones are the product made from a slurry of Portland cement, aggregates, and iron oxides molded to simulate natural stone like look-n-feel.

However, the classical style of production demand manual coloring and grain designing to alleviate repetitions. It is resulting in high cost but unique design more natural stone like impression even on close examinations.

Of course, don’t confuse veneer stones with faux veneer stones because it is a high-density polymer product closer to Styrofoam than natural stone.

Revolution in Stone Cutting

Recent advancements in slicing tools working on stones have enabled masons to cut thin slices, from one inch to six inches, of the natural stones available in the vicinity.

These thin tiles like slices have one side plain so masons can glue it on walls or floors using mortar mixture easily and bestow natural stone cladding on your hardscapes & landscapes.

Natural Stones vs. Manufactured Stones

After complete knowledge of both kinds of stones. Let’s compare both on following parameters.

Load Bearing Usage

Natural Stones:

Natural stones have inherent capacities to bear the load. However, load bearing capacities are different among stones types.

Some are sturdy while some fragile, but at least they can bear the load to some extent.

Manufactured Stones:

These products completely lack the load bearing capacities at all.

Therefore, those use as cladding the walls and other structural elements on your hardscapes and landscapes.

Size & Shapes

Real Stone:

It comes in two standard sizes blocks provide coverage of one retaining wall, i.e., approx. 9” and another is two retaining wall approx. 14” providing full-dimensional blocks.

In the old days, real stones used such those quarried with minor finishing. Real stones mostly come in square or rectangular cubs.

Veneer Stone:

Today, these real-stone slices use as veneer stone instead of the molded Cement-Concrete mixture with hand painted grains and colors. We can cut slices in any shape including square, rectangle, or diagonal.

The size of veneer stones may go down up to 1” in thickness and went up to 8” in thickness.

Weight & Thickness

Natural Stones:

Natural stones always are heavy to wight. For instance, a flagstone used for retaining wall construction may go up to 13 pounds per square foot. The main issue for real stone use is its heavy weight that constraints the transportation in availability, mode, and cost. Therefore, oversee exports costly and time-consuming affairs.

However, in the modern era, by using a giant wet saw, real stone quarried and cut into thin slices measuring about ¾” to 1-¾” in thickness. These thin slices used as covering layer over the local natural stones within 18” diameter limit.

Cultured Stones:

Cultured stones are 1/3 or ½ in weight of the real stones. Recently, thin slices of 2” to 6” thickness of real stone use to produced covering layer over the retaining wall or RCC structure.

It has saved a lot of labor and time on producing molded stones from the concrete-cement slurry.

Durability

Real Stones:

Real stones are less porous than manufactured stones. Weathering effects like sunlight, rain, heat, cold, and wind factors are hardly affecting the appearance of natural stones if any comes gradually that one might not be able to notice within years.

Veneer Stones:

Veneer stones when used as manufactured ones, they fade within years while slices cut from natural stones may stay a bit longer, but wear and tear weakening the attachments.

Look-n-Feel & Color Retreat

Real Stones:

Real stones are retaining their look and feel intact for decades. For example, the appearance of polished marbles remains as such over half or one of the century. Despite its installation on exterior sides, natural stones hardly fade in color and shine.

If the right chemicals used for the retreat of natural stones, natural colors are appearing again and stay for longer period.

Manufactured Stones:

The durability of colors of a cultured stone depends on pigmenting chemicals. However, colors fade over time. The variations in colors and patterns are the tempting purchase of the manufactured stones.

Repetitive patterns of grains and color styles on cultured stones is a big issue, and now thinner slices of natural stones can overcome those shortcomings.

Costs

Natural Stones:

Due to heavyweight, transportation is a costly affair for natural stones. Installation of natural stones demands skilled masonry and more labor or machines to uplift the heavy pieces of stones. The maintenance cost is significantly low.

Manufactured Stones:

Those are lightweight products equivalent to tiles. Therefore, quite cheaper in cost and installation. It is true that buying cost of both, natural and manufactured stones are the same, but differ in carriage and installation costs.

Maintenance is high and over time retreat or replacements are costly things with this option.

Conclusion:

Final Verdict

Applications of natural stones in ancient buildings are in the construction of retaining walls, columns, beams, foundation, and floor. Unfortunately, in the modern era, hardly anyone can allocate such big budget and expensive air projects that take years, not months to accomplish.

At another hand, cultured stones are fragile and fade fast. Moreover, it requires RCC structure and brick walls to support cladding. Therefore, modern architects always prefer to use both options in balance.

They know where to apply natural stones and where manufactured ones. If you want to check options available for natural stones, the best destination is ‘World of Stones’ in the USA. You also will get free consulting services to apply natural stones and cultured stones in your home, office, or business purpose buildings.

You will get a range of choices for natural stone selections, such as varieties of marbles for interiors and exteriors, limestone, quartzite, soapstone for countertops, cobblestones and flagstones for backyards and patios, brownstones for exteriors and structural elements, sandstones, bluestones, and local stones are for foundation and structures, and myriads of many others options to explore.

We cordially invite you to book your appointment for a face-to-face visit or explore our online and in-app catalogs for comfortable selections.

0 comments